Belonging category:MGP high and low temperature magnetic gear pump

Model:MGP

Flow range:0.06-16.8L/min

Voltage resistance:-

The pump body material is made of high-strength modified PEEK, the gear material is high-strength modified PEEK, the gear shaft is made of nano ceramic, the sealing standard is FFKM, and the overcurrent material is metal free, suitable for most solvents, acids and bases, organic halides, hydrocarbons, organic nitrides, inorganic reagents, and liquids that cannot come into contact with metals.

If the pump body material is customized with PTFE, the gear material is high-strength modified PTFE, the gear shaft is nano ceramic, the sealing material comes standard with FFKM, and the overcurrent material is metal free, suitable for strong acids such as concentrated sulfuric acid, concentrated nitric acid, concentrated hydrochloric acid, and benzenesulfonic acid.

No leakage; Low noise; Long service life; Corrosion resistance; Stable export pressure; No pulsation; Simple structure; Easy maintenance; Lightweight; The overcurrent material is non-metallic.

Micro cooling devices for aerospace vehicles, chemical and chemical industries (such as reagents, pharmaceuticals, film manufacturing, pharmaceutical equipment, etc.), various laser equipment and instruments, printing and coding machine manufacturing, high-performance color printing equipment, charging pile liquid cooling systems, molecular distillation equipment, methanol to hydrogen equipment, exhaust gas treatment systems, etc.

DC brushless motor, asynchronous motor, servo motor, etc.

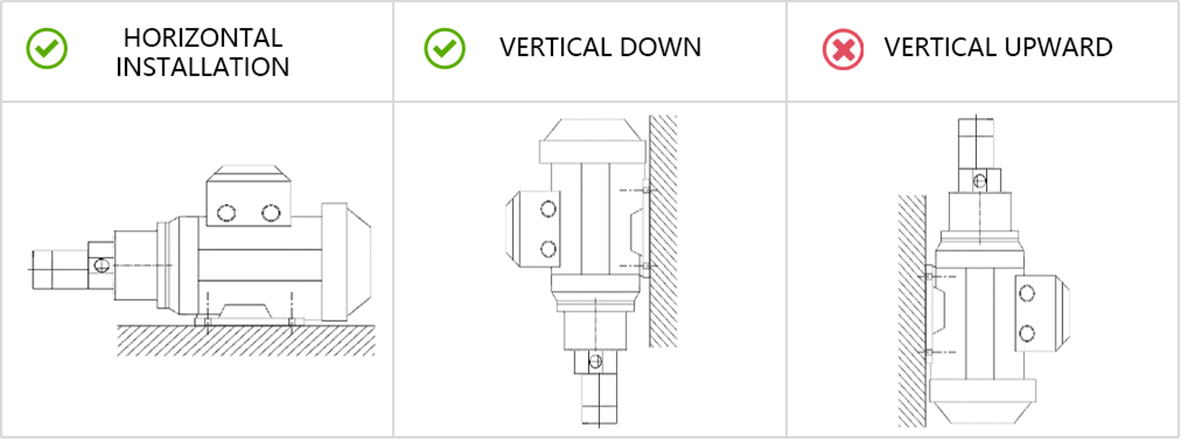

PUMP INSTALLATION

The installation position of the pump should be as close as possible to the medium source container. The diameter of the inlet and outlet pipelines should not be smaller than the size of the pump interface, and the length should be shortened as much as possible. If the inlet pipeline needs to be lengthened due to layout and installation site space limitations, the inlet diameter should be increased and the number of valves and bends at the pump inlet should be minimized as much as possible.

PIPELINE INSTALLATION

During pipeline installation: 1. Align with the inlet and outlet of the pump body as much as possible, and if possible, add pipeline support at appropriate positions; 2. Avoid the eccentric torque and weight of the pipeline directly acting on the pump, otherwise it may affect the sealing of the pump body, and long-term external forces can easily cause damage to the pump body and leakage.

Installation diagram

FILTER

The inlet of the pump should be equipped with a 25um or higher precision filter (preferably 400 mesh or higher precision). If the pump operates in a closed-loop system, the filter can also be installed at the outlet of the pump. It is recommended that the nominal flow rate of the filter be 1.5 times greater than the maximum flow rate of the pump to ensure the flow area of the medium and reduce the impact of the filter on the flow resistance of the pipeline.

USE PRESSURE

It is recommended to use within the pressure range that the pump can withstand. 1. Excessive system pressure can affect the sealing effect of the pump body; 2. Excessive pressure difference between imports and exports can cause magnetic slippage inside and outside the magnetic coupling. Excessive pressure fluctuations during use can also easily cause slippage in magnetic couplings.

SELF SUCTION

Gear pumps have strong self-priming function, but before starting, confirm that the gears have been wetted by the pumped medium.

DRY/REVERSE

Long term over speed drying can cause permanent damage to the pump. Please confirm that there is medium in the pump chamber or at least it has been wetted during operation. The pump should rotate clockwise. Short term reversal is acceptable, but prolonged continuous reversal will shorten the lifespan of the pump.